Quality

At Caparo, quality forms the bottom line of all our operations, enabling us to produce world-class forged deliverables for diverse industries.

In our relentless journey towards excellence, we have been meeting the specific requirements of global OEMs right since our beginning.

We have enforced a stringent quality monitoring system that has compliance with the latest global quality system standards. Be it performance, design, ongoing quality, or cost-effectiveness, achieving 100% customer satisfaction in all areas is what defines our quality policy.

Testing Facilities

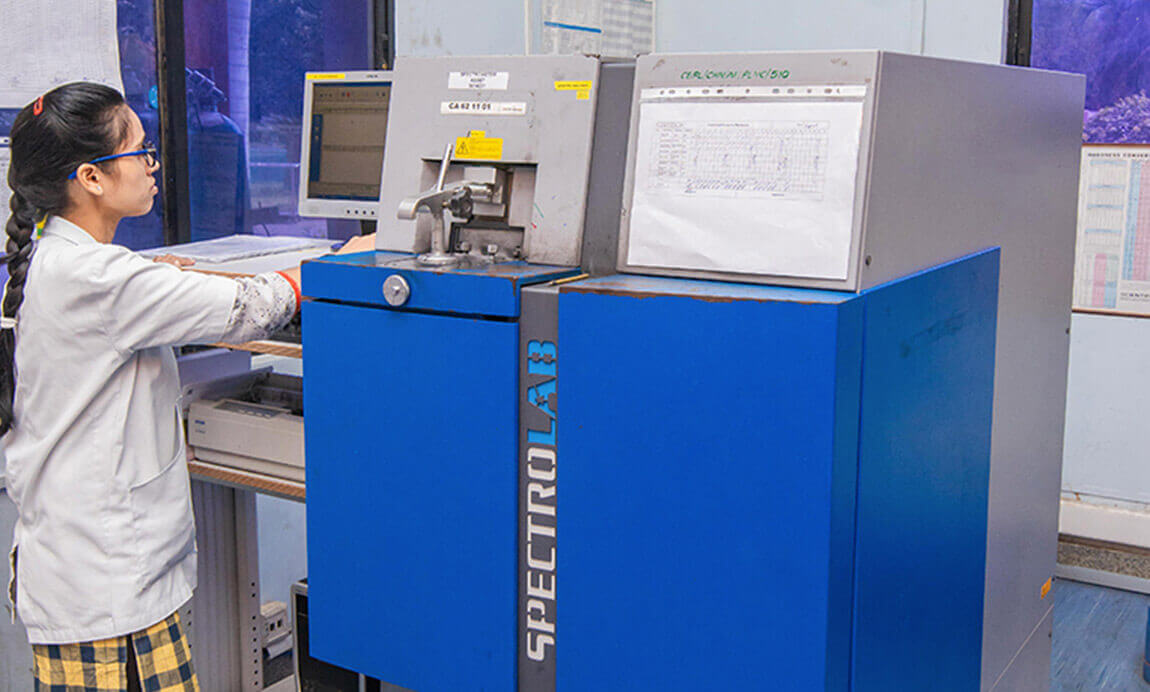

Our sophisticated inspection and testing facility capacitates us to deliver a wide range of cutting-edge forging solutions to global OEMs for various automotive and non-automotive applications with the utmost assurance of quality, durability, and reliability.

Our Strengths in the Testing Facility Include:

The lab is equipped with:

- Metallographic

- Chemical Composition Analysis

- Physical Properties Testing

- Micro-hardness Testing

- Eddy Current Testing

Certifications

- IATF 16949

Quality Control

- Dimensional Controls

- Die Dimensions

- Billet Dimensions

- In-process Output Dimensions

Metallurgical Controls

- Inclusions

- Chemical Composition

- Micro Structure & Grain Size

- Die & Component hardness

- Temperature & Time

Forging Equipment

- Process Parameters

- Lubrication

- Crack Detection & Visual Controls

- Physical Properties