Aviation is one such industry that has always kept pace with technological advancements. And, it has resulted in innovative and versatile aerospace fasteners. The bolts & nuts for aerospace engines play a crucial role in fixing. They hold different parts together. Some of the flying machines include the following:

● Commercial airplanes

● Military plane

● Jets

● Ballistic missiles, and

● Space-bound rockets.

The bolts & nuts for aerospace engines operate in extreme pressure and temperature conditions. So, their design and construction always need top-notch quality, durability, and reliability. The production of aerospace fasteners relies upon advanced technological developments. This blog will provide you with a thorough understanding of these aviation-specific fasteners.

Aerospace Fasteners: An Overview

Aerospace or plane fasteners are bolts & nuts for aerospace engines and other parts. Manufacturers produce them keeping in view the specific requirements of the aviation industry. These fasteners are lightweight, safe, and durable. It is because the aviation industry is very stringent in this regard. These fasteners also find applications in the following parts of a plane:

● Fuselage

● Wings

● Empennage

● Nose

● Pylon

● Nacelle

● Flight control surfaces, etc.

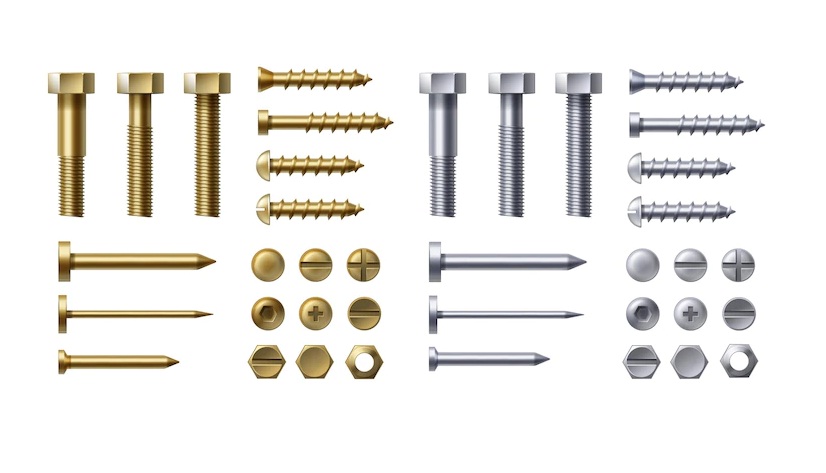

These fasteners also find application in commercial and military planes. They provide these flying machines with a great appearance and durability. These fasteners come in a huge variety. Some of them include bolts & nuts for aerospace engines, screws, rivets, and many more.

Characteristics of Aerospace Fasteners

Socket head cap screw manufacturers in India produce world-class aerospace or aviation fasteners. They are robust enough to withstand extreme gravity pressures. These fasteners determine the efficiency and safety of all the flying machines. The manufacturers also go beyond the call of duty to ensure their quality. They conduct stringent quality examinations during each phase of manufacturing. Each aviation fastener needs to pass some stringent standard certifications.

These fasteners always provide high-precision and high-quality attachments. Some of the major characteristics of the airplane fasteners include the following:

● These fasteners can perform well even under the harshest of conditions

● Aviation fasteners always offer high shear, fatigue, and tensile strength

● All come with self-sealing and self-locking capabilities

● They offer high corrosion as well as oxidation resistance

● They are lightweight on design and powerful on performance.

Quality standards for aerospace or airplane fasteners

The aerospace sector always calls for high-quality management standards. Some of the details about them are:

● Standards for organizations designing and manufacturing aerospace goods - AS9100, BS9100, and EN9100

● Standards for manufacturers and distributors of aerospace parts - AS9120, BS9120, and EN9120.

Some of the most common fasteners in the Aerospace Industry

Some of the most common bolts & nuts for aerospace engines and their applications:

Airplane bolts

Airplane bolts are the most important tools used in the aerospace industry. Standard and socket head cap screw manufacturers produce them using the following:

● Unplated corrosion-resistant steel

● Zinc plated corrosion-resistant steel

● Cadmium or anodized aluminum alloys.

The variety in aircrafts’ bolts includes:

● MS bolts

● Close tolerance bolts

● NAS internal wrenching, and

● AN bolts.

Airplane nuts

Airplane nuts are fasteners with threads on them. They are among the most important bolts & nuts for aerospace engines. Manufacturers produce them using the following materials:

● Cadmium plated carbon steel

● Stainless steel, or

● Anodized 2024T aluminum alloy.

Plane nuts find applications always in conjunction with a mating bolt or screw. Major types of these nuts include self-locking and non-locking.

Airplane screws

Some leading socket head cap screw manufacturers produce plane screws. These screws are an important part of the thread-fastening method with a helical edge. Manufacturers often use some lower-strength materials to manufacture them.

Airplane rivets

Plane rivets come with a smooth cylindrical shaft. They have a head on one end. They find applications in joining either two or more pieces of materials. These pieces include metal sheets or even plates. The shank of a rivet finds a position in the matched holes. And, the manufacturers upset the tip for producing a second head. Thus, the rivets clamp the two parts together.

Aerospace Collars (Lock Bolt Rivet)

Aerospace Collars (Lock Bolt Rivet) fit with the lock bolt rivets. They provide support in attaching the bolt to the concerned object. Aerospace Collars (Lock Bolt Rivet) have compatible metal alloy bodies.

Aerospace Fastener Materials

Aerospace fasteners exhibit different types of incredible characteristics. And, the construction material determines these features. Some leading socket head cap screw manufacturers use the following materials:

● Aluminum

● Steel

● Titanium

● Superalloys

Manufacturers use all the above materials to produce bolts & nuts for aerospace engines. They also take some special calls and use alloys to serve the purpose. Superalloys are the combination of either two or even more metals or materials. They use superalloys where standard materials fail to serve the purpose.

Aerospace Fasteners manufacturing in India

India has progressed like never before in the field of aerospace fasteners manufacturing. Indian manufacturers have specialized in in-house manufacturing. They are manufacturing a wide range of high-tensile standard and special fasteners. Today, these Indian manufacturers are supplying fasteners to almost all Automobile OEMs. Some of the top highlights about Indian aerospace fasteners manufacturers include the following:

● The pool of experienced designers and engineers

● Unrivaled expertise and deep understanding of the new-age product designs

● Unmatched capabilities in CAD and NAGSIM software

● Advanced product planning strategy

● Ability to create better fastener designs

● Ability to customize the fasteners as per the ever-evolving needs

● Ability to create and deliver an outstanding and infallible range of fasteners

● State-of-the-art facility for wire processing

● A comprehensive inspection of raw materials for chemical composition and forging ability

● Specialized Research and Development capabilities

● Intensive research to understand the specific needs of customers

● Ability to work in continuation with the ever-changing market and customer needs.

Concluding Remarks

Caparo is among India’s leading socket head cap screw manufacturers. The company also manufactures bolts & nuts for aerospace engines. The company has established itself as a reliable supplier of fasteners. Moreover, Caparo’s capabilities in manufacturing aerospace fasters are also exemplary. The company ensures zero defects in its entire products range. It conducts many quality checks including a dimensional and metallurgical inspection. It makes use of an Automatic Optical Bolt Sorting Machine.